The supply chain is a complex web of suppliers, manufacturers, and retailers that need to work together to get products from supplier to customer. Every link in the chain is important, and any disruption can have a ripple effect throughout the entire system.

That’s why it’s essential to have a reliable way to monitor the supply chain and detect potential problems before they cause serious disruptions. Here are just some of the ways supply chain monitoring can help your business stay competitive.

What Is Supply Chain Monitoring?

Supply chain monitoring involves using a set of tools, such as analytic software, to track and assess the performance of supply chain operations.

Supply chain monitoring tools can be used to track goods and services, inventory levels, raw materials, supply and demand trends, production schedules, and delivery timelines. Supply chain monitoring can also involve tracking supplier performance, assessing customer satisfaction levels, and auditing internal processes.

Supply chain monitoring is a critical part of effective supply chain management (SCM), as it helps businesses to identify and remedy issues in global supply chains that could impact business operations.

Supply chain monitoring is also important for identifying opportunities for cost savings, demand planning, inventory management, and supply chain management process improvements.

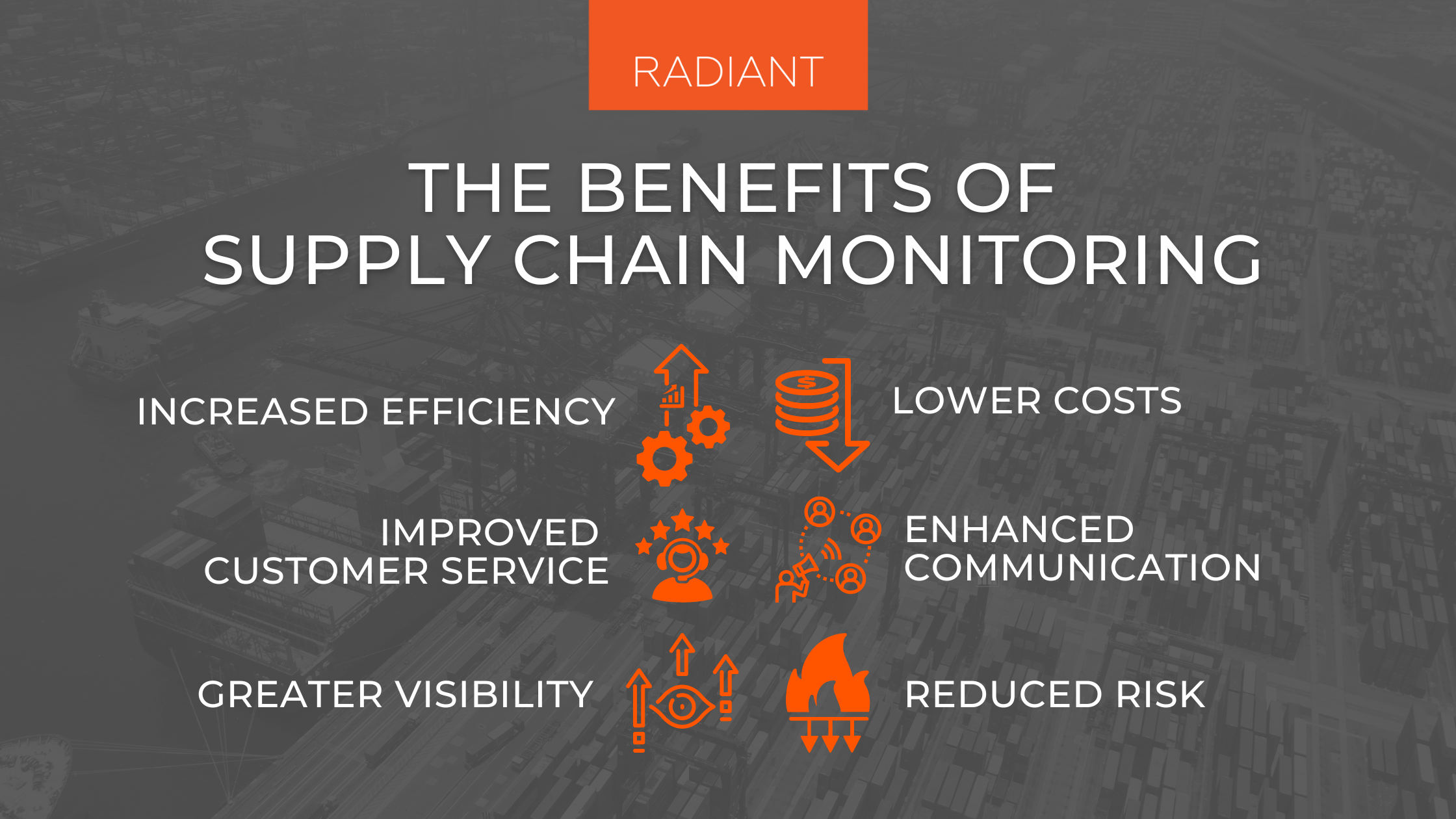

What Are The Benefits of Supply Chain Monitoring?

1) Increased Efficiency: Supply chain monitoring can help to increase the efficiency of your supply chain by providing visibility into all aspects of the supply chain.

By having visibility into where your products are at all times, you can identify bottlenecks and other issues that may be causing delays.

Additionally, you can use supply chain data to optimize routes and improve communication between different members of the supply chain.

2) Lower Costs: In addition to increasing efficiency, supply chain monitoring can also help to reduce costs.

By having visibility into the supply chain, you can identify areas where costs can be reduced. For example, you may be able to negotiate better rates with suppliers or find cheaper shipping options.

Additionally, you may be able to reduce inventory levels by knowing exactly when products or services will be delivered.

3) Improved Customer Service: Supply chain monitoring can also improve order management and customer service by ensuring that customers receive their orders on time.

By tracking orders throughout the supply chain, you can ensure that customers receive up-to-date information on the status of their order and lead time.

Additionally, you can use data from the supply chain to improve your forecasting accuracy, which can help to avoid stock outs and other customer service issues.

4) Reduced Risk: Another benefit of supply chain monitoring is that it can help to reduce risk through improved supply chain planning and execution.

By having visibility into the supply chain, you can identify potential problems before they occur. For example, if a supplier is consistently late with deliveries, you can find a new supplier before your business is affected.

Additionally, if there are issues with a particular product, you can remove it from the market quickly to avoid any negative impacts on your business.

5) Greater Visibility: One of the primary benefits of supply chain monitoring is that it increases visibility into the supply chain.

By tracking products throughout the supply process, you can see exactly where they are at all times. This information can be used to make decisions about where to source products, how to route shipments, and how to allocate resources.

Additionally, this information can be used to improve communication between different members of the supply chain.

6) Enhanced Communication: Another benefit of increased supply chain visibility is improved communication between different members of the supply chain.

When everyone has access to accurate supply chain analytics about where products are at all times, it becomes easier to coordinate activities and avoid potential problems.

Additionally, this information can be used to improve communication between different departments within your own company.

What Challenges Does Supply Chain Monitoring Present?

Supply chain monitoring presents a number of challenges, from the sheer volume of data that must be collected and processed to the need for real-time visibility. However, these challenges can be overcome with the right supply chain monitoring tools.

For example, data collection can be automated using IoT sensors and RFID tags, and data analysis can be performed using machine learning algorithms.

Furthermore, supply chain visibility can be improved using dashboard interfaces that provide real-time insights into supply chain performance.

By overcoming these challenges, supply chain monitoring can help organizations improve their operational efficiency and avoid supply disruptions.

How Does Supply Chain Monitoring Work? What Technologies Are Used To Make It Happen?

There are a number of different supply chain monitoring tools available, each with its own advantages and disadvantages. Some common supply chain monitoring tools include:

– RFID Tags: Radio Frequency Identification (RFID) tags are small devices that can be attached to products or materials. RFID tags emit a signal that can be detected by special scanners called RFID readers.

This makes them ideal for tracking the movement of products through a supply chain. However, RFID tags can be expensive, and they require special infrastructure to work properly.

– GPS Tracking: GPS tracking systems use satellite signals to track the location of objects in real-time. This information can be used to track the movement of products through a supply chain.

GPS tracking systems are less expensive than RFID systems, but they only provide information about location, not product condition.

– BLE Beacon Tags: BLE beacons are small, battery-powered devices that emit a Bluetooth Low Energy (BLE) signal that can be detected by nearby devices, such as smartphones. The signal emitted by a BLE beacon contains information about the beacon’s location.

BLE beacon tags are placed on products or containers, and the signal emitted by the beacon tag is used to track the location of the product or container throughout the supply chain.

BLE beacons are less expensive than other types of tracking devices, they have a long battery life, they’re easy to install, and they’re low maintenance.

– Barcodes: The most common supply chain monitoring tool is the barcode. Barcodes are machine-readable codes that are attached to products and containers.

When a product or container is scanned with a barcode reader, the barcode reader can identify the product or container and track its location within the supply chain.

While barcodes are common and inexpensive, they require a line-of-sight to be read and may be lost or damaged as products move through the supply chain.

Technology is constantly evolving, and new supply chain monitoring tools are being developed all the time. However, the basic principle remains the same: supply chain monitoring is essential for supply chain management, and various technologies can be used to make it happen.

How To Choose The Right Supply Chain Monitoring Tools For Your Business

If you’re in charge of supply chain management for your business, you know that supply chain monitoring is a critical part of your job.

You need to be able to track your inventory levels, shipments, and other asset data in real-time so that you can make informed decisions about where to focus your resources.

But with so many supply chain monitoring tools on the market, how do you know which one is right for your business?

Here are a few factors to consider when choosing supply chain monitoring tools:

– Ease of Use: You and your team will need to be able to quickly learn how to use the tool and navigate its interface. Otherwise, it will just add frustration and wasted time to your already busy days.

– Functionality: Make sure the tool you choose offers the specific features you need. For example, if you need to track international shipments, look for a tool that offers global visibility.

– Integration: Can the supply chain monitoring tool integrate with your existing enterprise resource planning (ERP) system? This is important for maintaining efficient data flow between systems.

– Support: Does the vendor offer customer support in case you have questions or run into problems? You should be able to reach someone easily by phone or email.

Choosing the right supply chain monitoring tools doesn’t have to be overwhelming. By keeping these factors in mind, you can narrow down your options and find the right solution for your business.

Achieve Real-Time Visibility Into Your Supply Chain With Radiant’s Asset Tracking Solution

Understanding what supply chain monitoring is, its benefits, how it works, and the challenges it presents will help you determine whether this technology can help your business meet its goals.

Selecting the right supply chain monitoring tools is essential to achieving real-time visibility into your assets and inventory.

Radiant’s asset tracking solution provides businesses with end-to-end accuracy and transparency throughout their entire operation. Request a demo below to see how our asset tracking solution can benefit your business.

Last Updated on October 18, 2022 by Radiant