Supply chain management is an essential part of any business. It’s the process that ensures that the right products and materials are delivered to the right places at the right times.

RFID technology has been shown to be an effective way to manage supply chain processes, but not all businesses are sure if it’s worth the investment.

In this blog post, we’ll take a closer look at RFID technology and explore some of its benefits for supply chain management. So, if you’re curious about RFID and how it could help your supply chain, keep reading.

What Is RFID Technology? How Does RFID Work?

RFID stands for radio-frequency identification. This technology uses radio waves to transmit data between a tag and a reader.

RFID tags are often used for tracking purposes, as they can store information about the item to which they are attached. RFID tags are made up of two parts: an antenna and a chip. The antenna is used to receive and transmit radio waves, while the chip stores information about the tagged item.

When an RFID reader comes within range of an RFID tag, it transmits a signal that activates the tag. The tag then responds by transmitting its stored data back to the RFID scanners. This real-time information can be used for a variety of purposes, such as tracking the location of inventory or monitoring the condition of goods in transit.

Thanks to its many applications, RFID technology is quickly becoming an essential tool in a variety of industries.

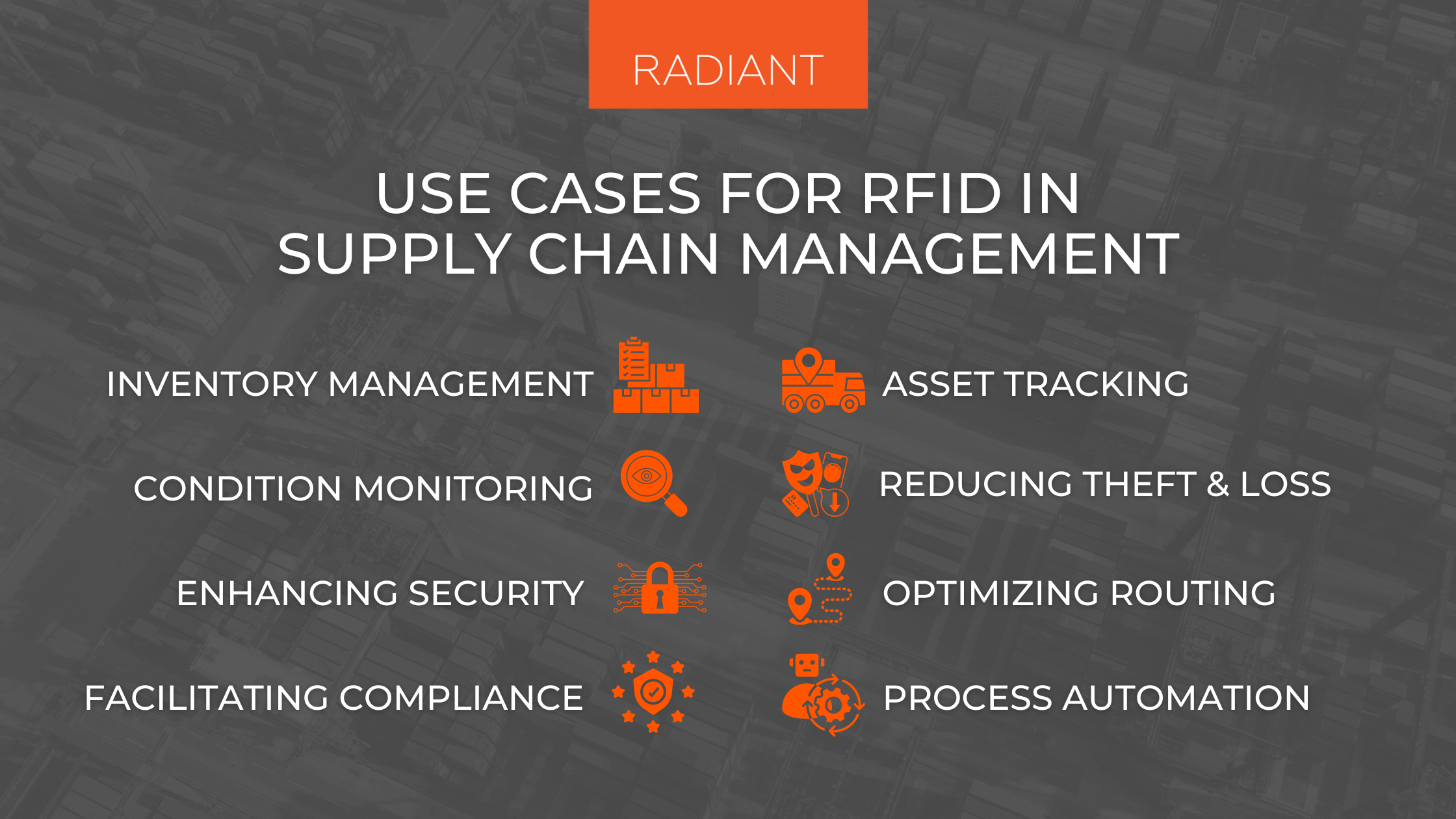

Use Cases For RFID In Supply Chain Management

RFID technology is increasingly being used in supply chain management in a variety of ways.

– Inventory Management: One of the most common use cases for RFID technology in supply chain management is managing inventory. RFID tags can be attached to products or packaging, and then scanned to track the movement of goods throughout the supply chain, helping to improve inventory accuracy. This information can be used to optimize stock levels at distribution centers, identify bottlenecks, and improve overall efficiency.

– Asset Tracking: Another common use case for RFID in supply chain management is tracking assets. RFID tags can be used to track high-value items such as raw materials, tools, machinery, and vehicles. This information can help organizations to keep track of their assets and prevent theft or loss.

– Monitoring Environmental Conditions: RFID tags can also be used to monitor environmental conditions such as temperature and humidity. This information can be used to ensure that products are stored in optimal conditions and that they are not damaged during transport.

– Reducing Theft: RFID tags can also be used to deter theft and product tampering. If an RFID tag is removed from a product, it can trigger an alarm or alert security personnel. Additionally, RFID tags can be used to track products that have been stolen, making it easier to recover them.

– Enhancing Security: In addition to reducing theft, RFID tags can also be used to enhance security throughout the supply chain. The tags can be used to track the movement of dangerous goods, such as chemicals or explosives, and ensure that these items are not delivered to unauthorized locations.

– Optimizing Transportation & Routing: RFID can also be used to optimize transportation in a supply chain. This information can be used to track the location of vehicles and shipments and ensure that they are being routed efficiently

– Facilitating Compliance With Regulations: RFID enables compliance with regulations in a supply chain. This is because RFID tags can be used to track the location of products, as well as the conditions in that they are being stored. This information can then be used to ensure that products are being handled in accordance with all relevant regulations.

– Automating Processes: RFID tags can be used to automate various processes throughout the supply chain, such as stock management and order fulfillment. By tracking the location of products in real time, businesses can automatically update inventory levels and trigger alerts when items need to be restocked or shipped out. Additionally, RFID tags can be used to automatically generate packing lists and shipping labels, reducing human errors and saving time.

As RFID technology continues to evolve, new and innovative use cases for RFID in supply chain management are sure to emerge.

The Benefits of RFID In Supply Chain Management

RFID in supply chain management can provide many benefits over traditional methods, including:

- Automatic Data Collection

One of the primary benefits of RFID technology is that it allows for automatic data collection. RFID tags can be read automatically, which means that data can be collected without the need for manual input. This can help to improve the accuracy of data and also reduces the amount of time needed to collect it.

- Real-Time Tracking

RFID technology also allows for real-time tracking of assets. This means that businesses can always know exactly where their products are and how many they have in stock. This real-time information can be used to improve inventory management and also to make sure that products are always available when customers want them.

- Reduced Costs

Another benefit of RFID technology is that it can help to reduce costs. For example, RFID tags do not need to be manually scanned like barcodes do, which can save businesses money on labor costs. Additionally, RFID tags are more durable than barcodes, which means they will last longer and will not need to be replaced as often.

- Increased Efficiency

RFID tags can help to increase the efficiency of supply chain management by allowing for real-time tracking of inventory. This means that businesses can know exactly where their products are at all times, which can help to reduce the amount of time and money that is wasted on lost or misplaced items. Additionally, RFID tags can help to automate the process of inventory management, which can further increase efficiency.

- Improved Customer Service

The increased accuracy and efficiency made possible by RFID technology can also lead to improved customer service. For example, if a customer orders a product that is out of stock, businesses can use RFID tags to quickly locate and deliver the product to the customer’s doorstep. Additionally, businesses can use RFID tags to keep track of customer orders and ensure that they are delivered on time.

- Greater Visibility

Another benefit of RFID technology is increased visibility throughout the supply chain. For example, RFID tags can be used to track the location of inventory in real time, which allows managers to quickly identify any potential problems or delays so that they can work with their supply chain partners to address them. Additionally, RFID data can be integrated with other business systems such as enterprise resource planning (ERP) or warehouse management systems (WMS), which provides even greater visibility into all aspects of the supply chain.

- Improved Decision Making

Finally, another benefit of RFID technology is improved decision-making throughout the supply chain. For example, RFID data can be used to generate reports that provide insights into trends such as product popularity or seasonal fluctuations. Additionally, this data can be combined with other data sources such as weather data or demographic data.

In addition, RFID can be used to create flexible and scalable supply chain management solutions that can be adapted to changing business needs. RFID tags are becoming smaller, more affordable, and more widely available, making RFID an increasingly attractive option for supply chain management.

As a result, RFID in supply chain management can provide significant benefits over traditional methods.

Challenges Of Implementing RFID In Supply Chain Management

RFID technology has the potential to revolutionize supply chain management, but implementing RFID systems can pose a number of challenges.

One of the key challenges is managing the data generated by RFID tags. Unlike barcodes, which simply store a product’s identification number, RFID tags can store a wealth of information about a product’s history, location, and condition. This data can be very helpful in managing inventory and tracking shipments, but it can also be overwhelming.

Another challenge is ensuring that RFID tags are read consistently and accurately. RFID tags can be blocked by metal or dirt, and they often need to be positioned just right in order to be read properly. This can make it difficult to track products throughout the supply chain.

Despite these challenges, RFID technology offers many benefits that make it worth exploring for any business that relies on supply chain management. With its ability to track individual items, RFID has the potential to greatly improve efficiency and accuracy in the supply chain.

Achieve Greater Efficiency and Accuracy With RFID In Supply Chain Management

RFID technology is becoming more prevalent as businesses strive for greater efficiency and accuracy in their supply chains. In this post, we’ve outlined what RFID is, how it works, and some of the benefits and challenges associated with its implementation.

If you’re looking to get started with RFID in your own business or are simply interested in learning more about this exciting technology, explore our RFID solution and request your demo below.

Last Updated on October 7, 2022 by Radiant