Since the dawn of manufacturing, businesses have been seeking new and more efficient techniques to streamline their operations – and with today’s advancing technology, warehouses are no exception.

By implementing a Radio Frequency Identification (RFID) warehouse management system into their operation, businesses can achieve unparalleled, previously unheard-of efficiency.

With increased accuracy in item tracking, security for staff and assets, decreased labor costs, and far-reaching operational insights – RFID is modernizing every aspect of the warehousing process from receiving through shipping.

In this blog post, we will explore how RFID asset tracking solutions can help business leaders unlock a world of possibilities for efficiently managing resources in their warehouses.

What is an RFID Warehouse Management System?

An RFID warehouse management system is a technology-driven solution that streamlines and simplifies warehouse operations by using radio frequency identification (RFID) technology. It is a game-changing radio wave technology that enables warehouse personnel to perform real-time tracking and inventory management without manual data entry or barcode scanning.

With an RFID system, businesses can streamline inventory management processes, reduce human error, and increase operational efficiency.

This innovative system uses electromagnetic fields to automatically identify and track RFID tags attached to products or pallets as they move through the warehouse, without a direct line of sight required.

By integrating RFID technology, businesses can enhance their warehouse operations and stay ahead of the competition. It is a revolutionary technology that any company dealing with inventory management must embrace.

How Does an RFID Warehouse Management System Help to Streamline Operations?

The implementation of a reliable RFID warehouse management system can be a game-changer in the world of logistics and warehousing. Not only does this technology allow for better efficiency, but it also aids in cost reduction and inventory management.

With the help of RFID readers and tags, warehouse managers can streamline operations such as receiving, stocking, and order processing. These systems eliminate the need for manual scanning and data entry, significantly reducing the chances of errors and misplacements.

Furthermore, RFID technology helps provide real-time visibility into inventory levels and locations, which can help prevent out-of-stock situations and enable just-in-time deliveries.

By utilizing an RFID warehouse management system, businesses can easily optimize their supply chain and stay ahead of their competitors in today’s fast-paced market.

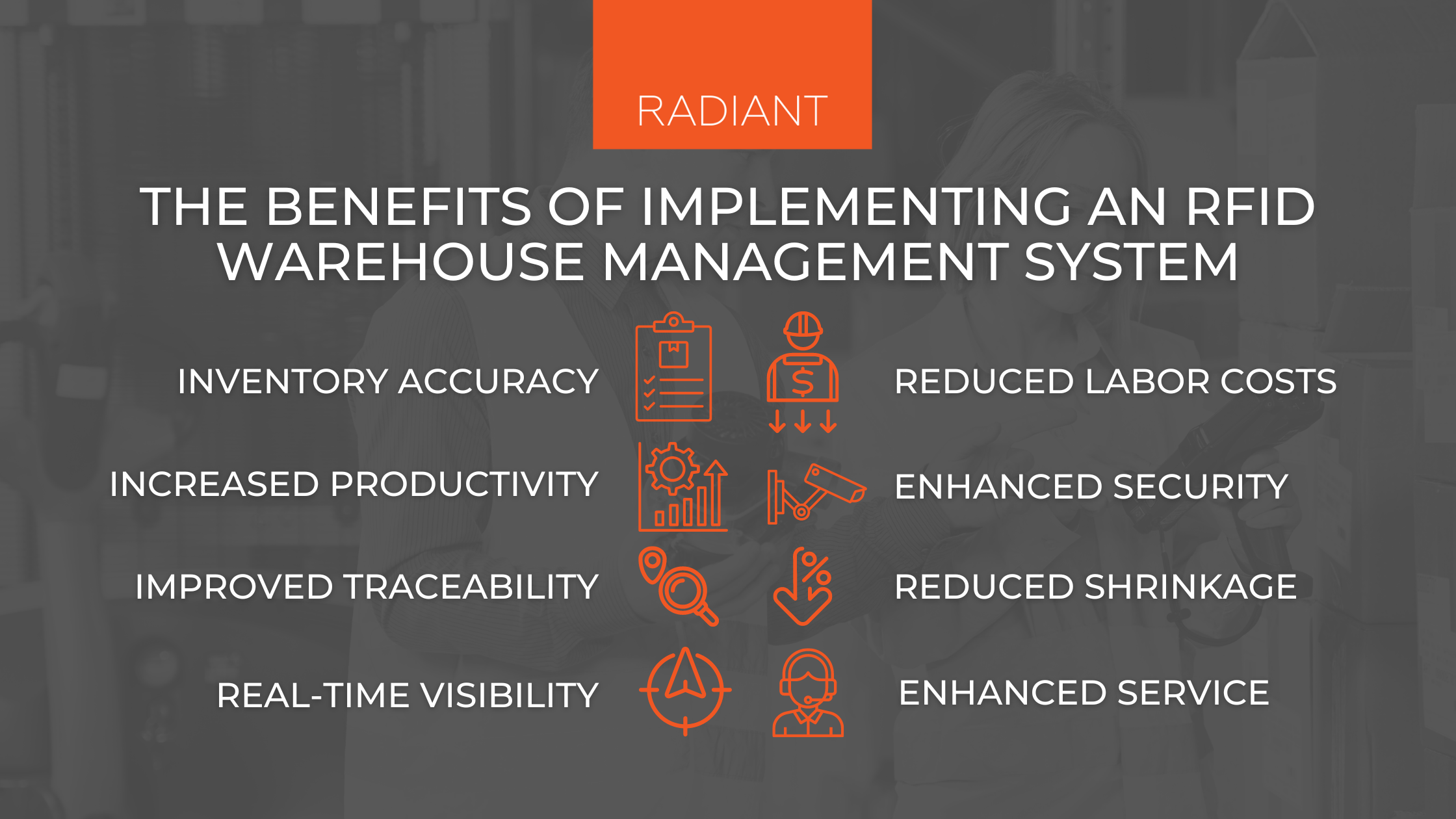

The Benefits of Implementing an RFID Warehouse Management System

Implementing an RFID Warehouse Management system brings many benefits to businesses that manage warehousing operations:

Improved Inventory Accuracy

Implementing an RFID Warehouse Management System can help to improve inventory accuracy by providing real-time data on the location and quantity of items in the warehouse. This helps to reduce errors and ensure that all inventory is accounted for, leading to more efficient operations.

Reduced Labor Costs

RFID systems can also help to reduce labor costs by automating many tasks that would otherwise require manual labor. For example, an RFID system can track items throughout the warehouse, eliminating the need for employees to count and locate items manually. This can save time and money, making it a cost-effective solution for businesses.

Increased Productivity

By automating many of the tasks associated with warehouse management, an RFID system can help increase warehouse productivity. By streamlining processes such as tracking inventory or locating items, warehouses can operate more efficiently and get more done in less time. This can lead to higher business profits and improved customer satisfaction due to faster order fulfillment times.

Enhanced Security

RFID systems provide enhanced security measures by allowing warehouses to track items throughout the facility at all times. With this type of system in place, warehouses are better equipped to prevent theft or loss of valuable inventory since they better understand where each item is located at any given time.

Improved Traceability

An RFID warehouse management system also provides improved traceability by allowing warehouses to quickly identify where products were sourced from or which customers they were shipped to. This helps businesses ensure compliance with regulations and improve their ability to respond quickly in case of product recalls or other issues with their inventory.

Reduced Shrinkage

Shrinkage is a major issue for many warehouses due to theft or inaccurate record-keeping practices, but an RFID system can help reduce shrinkage significantly by providing accurate records of what’s coming into and leaving the warehouse at all times. This ensures that only authorized personnel have access to certain products and helps prevent any unauthorized removal of goods from the premises.

Real-Time Visibility

Another benefit of using an RFID Warehouse Management System is its ability to provide real-time visibility into what’s happening in the warehouse at any given moment, giving managers greater insight into how operations are running to make adjustments based on current conditions. This allows them to make more informed decisions about allocating resources and optimizing processes within their organization for maximum efficiency and profitability over time.

Enhanced Customer Service

With an RFID warehouse management system in place, warehouses are better equipped to provide enhanced customer service by quickly locating orders or answering inquiries regarding product availability or delivery status without delay, thanks to its real-time visibility capabilities mentioned above. This helps create a better overall customer experience, leading directly to increased loyalty levels over time as customers return repeatedly due to the quality service they receive every time they interact with your business.

Adopting an RFID Warehouse Management system can be a game-changer for businesses looking to optimize operations and enhance their bottom line.

Understanding the Limitations of an RFID Warehouse Management System

As with any technology, there are limitations to utilizing an RFID warehouse management system. While it offers significant benefits, such as improved inventory tracking accuracy and reduced labor costs, there are also some downsides.

One major limitation is the cost of implementation and maintenance. It can be a significant investment and ongoing expense to keep up with new technology updates and improvements.

Another consideration is the range and accuracy of the RFID tags themselves. Depending on the size and layout of the warehouse, tags might not be able to be read from certain areas.

Considering these limitations before implementing an RFID warehouse management system is important. However, with proper planning and implementation, the benefits can outweigh the potential drawbacks.

Tips for a Successful Implementation of an RFID Warehouse Management System

Utilizing RFID for warehouse management is a game-changer for businesses that want to streamline operations. But it’s not just a matter of implementing the technology and expecting it to work smoothly overnight.

There are tips and tricks that will ensure the successful integration and implementation of RFID technology into warehouse management operations.

First and foremost, it’s important to clearly understand your goals and objectives for using RFID in your warehouse.

Select the right RFID tags and readers to match your warehouse’s unique needs from there.

Training your team on how to use and integrate the new technology into their workflows is also crucial.

By following these tips and working with an experienced RFID provider, you can confidently and successfully incorporate RFID into your warehouse management process and enjoy its many benefits, including improved accuracy, efficiency, and real-time visibility.

Determining if an RFID Warehouse Management System is right for your Business

Implementing an RFID warehouse management system into your operations can help to make processes faster, smarter, and more efficient. From organizing inventory to optimizing time, an RFID system can provide significant value to businesses of any size or scope.

Though there are certain limitations to the technology which must be accounted for to have a successful implementation, understanding these beforehand ensures that you can best use your system for maximum benefit.

When evaluating whether an RFID warehouse management system is right for your business, consider how this technology will help you maximize speed and improve efficiency throughout your workflow.

At Radiant, we believe in the power of IoT asset tracking solutions to streamline operations and save time on mundane tasks. We invite you to explore our RFID solution and request a demo below – join us as we continue driving innovation through IoT technologies.

Last Updated on August 22, 2023 by Radiant