When you’re running a business, it’s important to keep track of your inventory and assets. After all, if you don’t know what you have and what’s coming in and out, you can’t make sure that your shelves are stocked with the things that your customers want.

But even if you’re keeping careful track of your physical inventory, there’s still a chance that you could fall victim to phantom inventory.

What is phantom inventory, and how can you make sure that it doesn’t creep into your inventory record? Let’s take a look.

What Is Phantom Inventory?

Phantom inventory can be defined as “the discrepancy between a company’s physical stock and its records.”

In other words, phantom inventory is inventory accounting that is reflected in a company’s books as on-hand but isn’t physically present or available for sale at the store location. Simply put, phantom inventory exists on paper, but not in reality.

In addition, phantom inventory can also be the result of damaged or outdated merchandise. If a product is damaged, it can’t be sold, and if it’s outdated, it may no longer be in demand.

Either way, phantom inventory takes up valuable space and resources without providing any benefits. Rather, phantom inventory can have far-reaching consequences for a business.

For example, it can lead to inventory turnover issues, as businesses may order more inventory than they actually need. Additionally, it can throw off the reorder point, resulting in periods of time when there is too much or too little inventory on hand at the store level.

Finally, phantom inventory can make it difficult to track down items when they are needed, as the actual storage location of the inventory may be unknown.

Ultimately, phantom inventory can cause problems for businesses if it is not carefully managed. While it may seem like a small issue, it can have a big impact on a company’s operations.

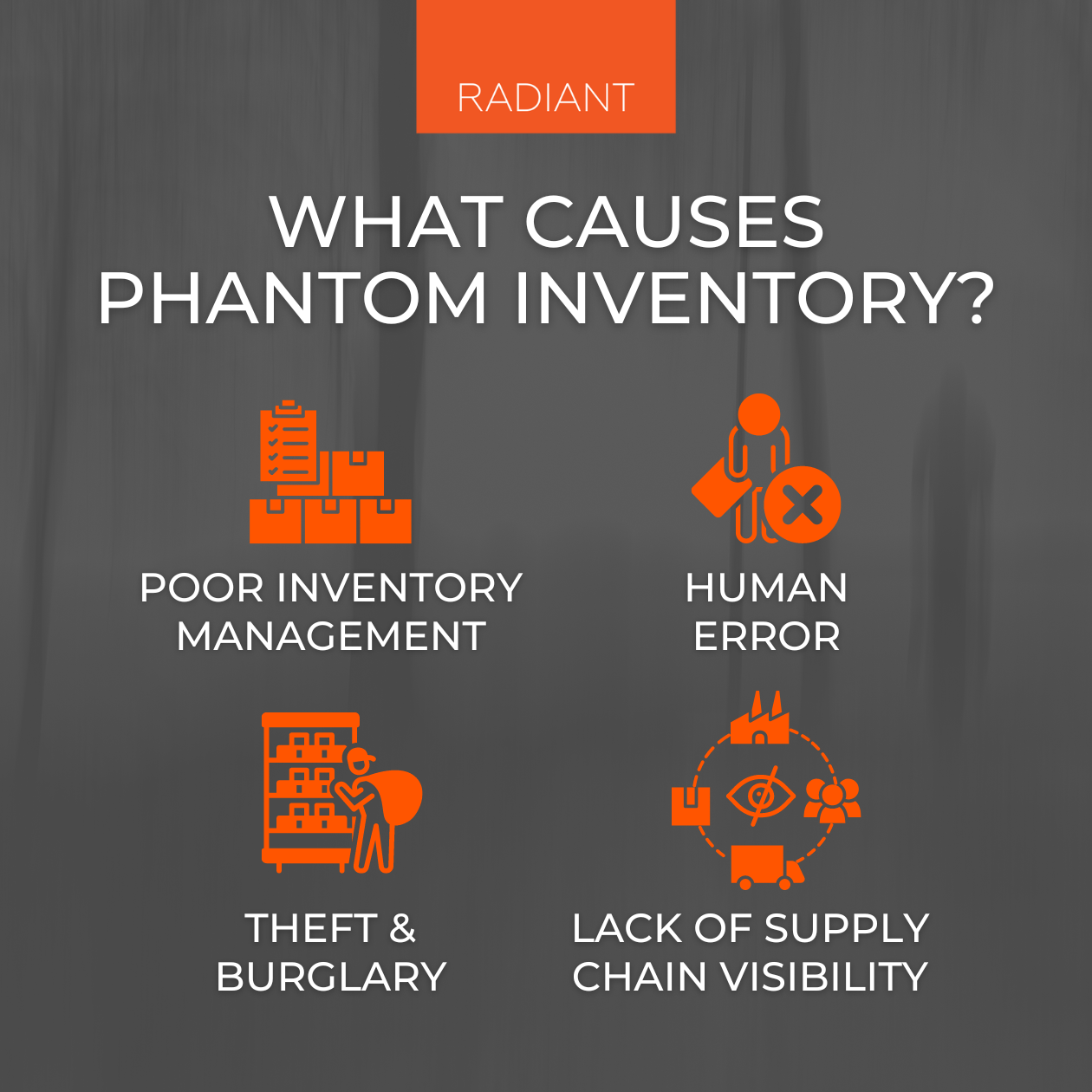

What Causes Phantom Inventory?

Phantom inventory is a problem that can plague businesses, brands, and retailers of all sizes and can occur for a number of reasons:

– Poor Inventory Management: Poor inventory management is often the root cause of phantom inventory. When businesses don’t have a clear idea of what they have in stock, it’s easy for items to get lost or misplaced.

As a result, businesses may order more inventory than they need, thinking they have less on hand than they actually do. This can lead to excess and unused inventory, tying up valuable resources that could be better spent elsewhere.

In addition, phantom inventory can cause stockouts and disruptions in the supply chain. When phantom units are removed from the inventory system, it can cause a sudden drop in inventory levels, leading to stockouts and disruptions in production.

To avoid phantom inventory, it is essential to have accurate and up-to-date inventory management practices in place.

– Human Error: Phantom inventory can be caused by a number of factors, but human error in the perpetual inventory system is often to blame.

One common cause is simply misplacing items or failing to properly update records. This can happen when items are moved around without being properly logged, or when employees forget to scan items into the system.

Another common cause of phantom inventory is incorrect data entry. This can occur when employees input the wrong data, or when they mistakenly duplicate entries.

In either case, the result is the same: phantom inventory that costs businesses time and money.

By taking steps to improve accuracy and communication, businesses can reduce the chances of phantom inventory occurring.

– Theft: Phantom inventory can also build up on a company’s books as a result of theft and inventory shrinkage.

If items are regularly stolen from a warehouse or store, the company may not realize that they are missing until an inventory count is conducted. At that point, the phantom inventory is revealed, and the company is forced to come up with the missing merchandise.

In some cases, this can be a major loss for the business. Not only does it mean that they are paying for goods that they do not have, but it also means that they are losing out on potential sales.

– Lack of Supply Chain Visibility: Lastly, a lack of supply chain visibility can lead to phantom inventory because it makes it difficult to track where inventory is and whether it’s in sellable condition.

If a company does not have visibility into its supply chain, then it may be difficult to track where products are and how they are moving through the system. This lack of visibility can ultimately lead to errors in forecasting and stocking, which can result in a build-up of phantom inventory, leading to wasted space, lost sales, and frustrated customers.

The best way to avoid this problem is to invest in supply chain visibility tools, like asset management software, that will give you real-time data analysis on your inventory levels. With this information, you’ll be able to avoid phantom inventory and keep your business running smoothly.

Regardless of the cause, phantom inventory can have a significant impact on a company’s bottom line.

The Impact of Phantom Inventory

While phantom inventory may not seem like a big deal, it can actually have a significant impact on a business.

Inventories are typically carried on a company’s balance sheet as an asset. However, if phantom inventory is present, this can artificially inflate the value of assets and give a false impression of profitability.

Additionally, phantom inventory can lead to costly write-downs and disruptions in the supply chain. If inventory levels are inaccurate, it can lead to stockouts and production disruptions, both of which can be costly for businesses.

Lastly, phantom inventory can damage relationships with customers and ultimately, result in lost sales. If customers cannot get the products they need when they need them, they may look elsewhere for a better experience. This can lead to lost sales and a decline in customer loyalty.

The same is true for suppliers. If they cannot rely on a company to accurately forecast demand, they may be hesitant to do business with them in the future. This could lead to higher prices and longer lead times, both of which can be detrimental to a business.

In short, phantom inventory is a drag on business efficiency, reputation, and profitability that should be avoided whenever possible.

How To Prevent Phantom Inventory From Haunting Your Business

Phantom inventory can be a real nightmare, causing disruptions in your supply chain and leading to lost sales and frustrated customers.

So how can you prevent phantom inventory from haunting your business? Preventing phantom inventory can be tricky, but there are a few steps you can take to reduce the chances of it occurring in your business.

1) Regularly Conduct Inventory Audits: These should be done at least once a year, and more often if you have a large or high-value inventory. The goal of an inventory audit is to count the physical units of inventory on hand and compare it to the reported, or “on paper”, quantity.

The audit should also include an inspection of the condition of the inventory to ensure that it is usable. By auditing inventory regularly, discrepancies can be discovered and corrected quickly, before they have a chance to grow into larger problems.

2) Implement a Cycle Count System: This involves counting a portion of your inventory on a regular basis (weekly or monthly). By conducting regular counts, businesses can ensure that their records are accurate and that they are not overstocking or understocking items.

In addition, cycle counting can help to identify errors and discrepancies in the system, which can then be corrected. Overall, implementing a cycle count system is an effective way to improve inventory management and prevent phantom inventory.

3) Invest in an Asset Tracking Solution: An asset tracking solution can help you keep track of your inventory so that you know what you have and where it is at all times. This information can help you make better decisions about what to stock and how to best utilize your available space.

Additionally, an asset tracking solution can alert you when items are close to becoming phantom inventory so that you can take steps to sell or dispose of them before they become a liability, while also cutting back on the time it takes to perform inventory audits and cycle counts.

Implementing an asset tracking solution is a smart way to help prevent phantom inventory and keep your business running smoothly.

By following these steps, you can help prevent phantom inventory and keep your business running smoothly.

Don’t Let Phantom Inventory Creep Into Your Books

No business wants to be haunted by phantom inventory, but it can happen to even the most well-run organization. By taking proactive measures such as regularly conducting inventory audits, implementing a cycle count system, and investing in an asset tracking solution, you can prevent phantom inventory from putting a damper on your business.

At Radiant, we offer a state-of-the-art asset tracking solution that can help you keep tabs on your assets and avoid costly inventory errors. Request a demo of our solution below and see how easy it is to get started.

Last Updated on October 10, 2022 by Radiant