When it comes to asset management, one of the most important decisions you’ll make is what type of tag to use. RFID tags and barcode tags are two common options, but which is the best choice for your business?

In this post, we’ll break down the advantages and disadvantages of each type of asset management tag – RFID vs Barcode – so you can make an informed decision. Stay tuned for our final verdict on which tagging system is best for your asset management needs.

What is RFID Technology, and What are RFID Tags?

RFID (radio frequency identification) is a technology that uses radio waves to identify and track objects. RFID tags are small devices that contain antennae and chips that store information about the tagged object.

There are two types of RFID tags – active and passive.

- Active RFID tags have their own power source, which allows them to transmit their signal over long distances (up to 100 meters).

- Passive RFID tags don’t have their own power source, so they must be placed close to the RFID scanner in order to be read.

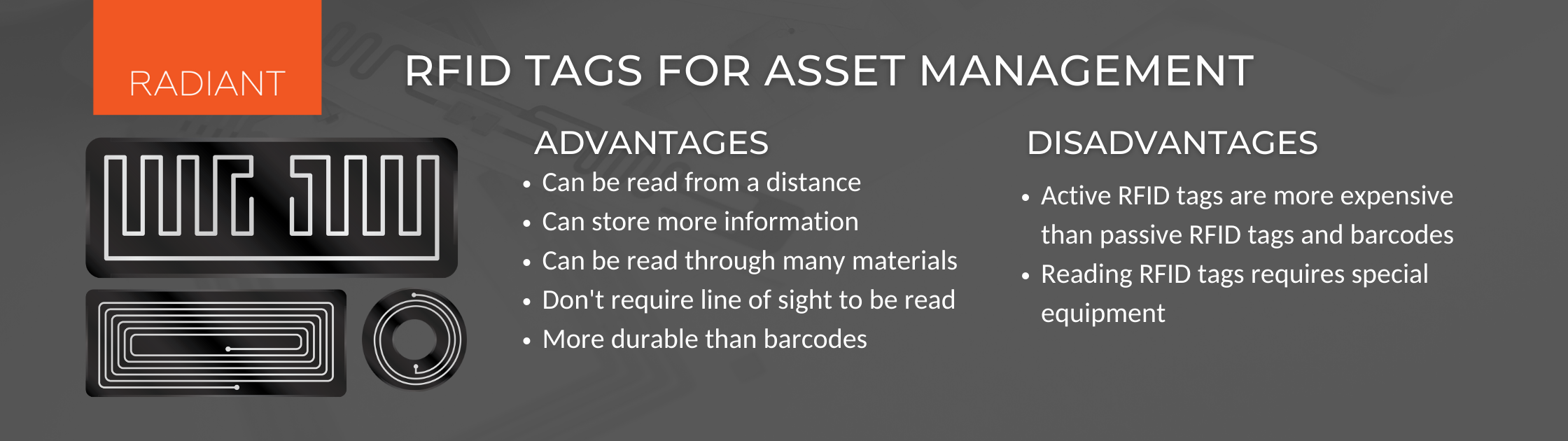

Let’s take a closer look at the advantages and disadvantages of RFID tags for asset management:

RFID Advantages:

– Can be read from a distance (up to 100 meters for active tags)

– Can store more information

– Can be read through many materials, including metal and water

– Don’t require line of sight to be read

– More durable than barcodes

RFID Disadvantages:

– Active RFID tags are more expensive than passive RFID tags, and barcodes

– Reading RFID tags requires special equipment

What is Barcode Technology, and What are Barcode Tags?

Barcode technology is a system that uses optical machine-readable tags consisting of black and white lines, squares, or hexagons for encoding information about the tagged object. Barcodes are read by scanning them with a barcode reader.

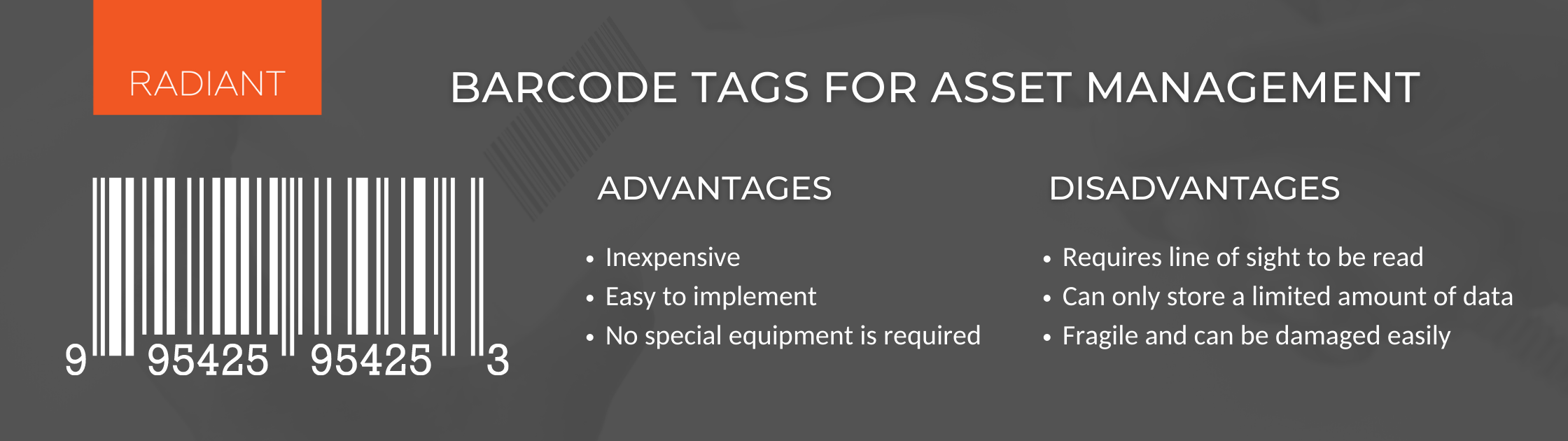

Let’s take a closer look at the advantages and disadvantages of barcode tags for asset management:

Barcode Advantages:

– Inexpensive

– Easy to implement

– No special equipment is required

Barcode Disadvantages:

– Must be placed close to the barcode scanner in order to be read (requires line of sight)

– Can only store a limited amount of information

– Fragile and can be damaged easily

Comparing RFID vs Barcode Technology

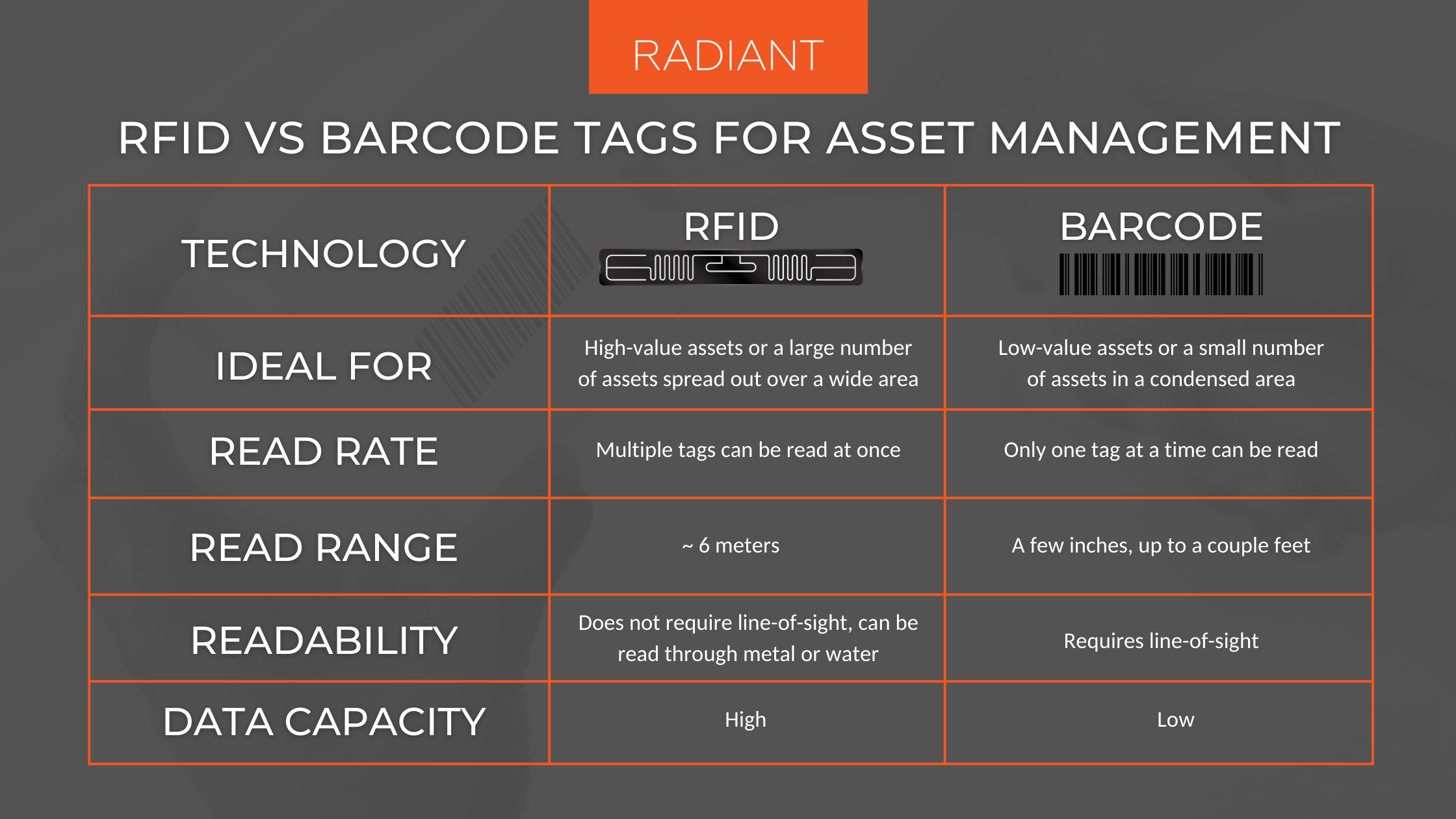

At first glance, these asset management tags may seem quite similar. After all, both are small, printed labels that can be attached to assets as unique identifiers. However, there are some important differences between these two technologies that should be taken into account when choosing a solution for asset management. Here’s a closer look at how RFID vs barcode technology compares:

RFID tags are able to store more information than barcodes, making them ideal for tracking complex assets. They also don’t require line of sight, meaning they can be read even if hidden from view. However, RFID tags are more expensive and can be more difficult to implement.

Barcodes, on the other hand, are less expensive and easier to implement than RFID tags. They also have a wide range of applications, making them suitable for a variety of asset tracking needs. However, barcodes require line of sight to be read, which means they can’t be used to track assets that are hidden from view. Additionally, barcodes can only be scanned one at a time, while RFID scanners can read multiple tags at once.

Ultimately, the best asset management solution will depend on the specific needs of the application.

Applications for Each Type of Tag: RFID vs Barcodes

RFID tags are best suited for tracking high-value assets or assets that are difficult to scan, such as those behind walls, on the tops of shelves or in water. They are also a good choice for companies that need to track a large number of assets, as the tags can be read quickly and from a distance.

Barcode tags are best suited for tracking low-value assets or assets that are easy to scan. They are also a good choice for companies that do not need to track a large number of assets. Barcode tags are less expensive than RFID tags and are easier to implement, making them a good choice for small businesses with assets within physical reach or businesses on a tight budget.

How is RFID vs Barcode Technology Used in Different Industries?

Barcodes and RFID tags are used in a variety of industries to track inventory, assets, and people. Barcodes are most commonly used in retail settings, where they are scanned at point of sale to track product information.

RFID tags are used in a variety of industries, including healthcare, manufacturing, and logistics. In healthcare, RFID tags are used to track patients, medications, and medical supplies. In manufacturing, RFID tags are used to track parts and products throughout the supply chain. And in logistics, RFID tags are used to track shipments and containers.

Each industry has different needs, but barcodes and RFID tags provide a common solution: a way to track and manage data.

What to Consider When Deciding Between RFID vs Barcode Technology

Deciding whether to use RFID vs barcode technology for asset or inventory management depends on a number of factors. Here are some key considerations to help you decide which option is best for your needs:

- Cost: One major difference between RFID vs barcode technology is the cost of implementation. Barcode systems are typically less expensive to set up, since they require only a scanner and barcode labels. RFID systems, on the other hand, require special tags or labels as well as RFID reader infrastructure.

- Accuracy: RFID tags can be read remotely, so there is no need to line up the tag in front of the scanner. This provides a significant advantage in accuracy over barcodes, which must be scanned individually.

- Ease of use: Barcode systems are generally easier to set up and use than RFID systems. This is due in part to the fact that they have been around longer and are thus more familiar to most people.

- Application: One final consideration is the intended application of the system. If you need to track assets that are moving quickly or at a distance, RFID is the better option. If you need to track static assets or those that are close by, barcode technology may be sufficient.

Both technologies have their advantages and disadvantages, so it’s important to weigh all factors before making a decision. By considering cost, accuracy, ease of use, and application, you’ll be able to choose the option that’s best for your needs.

At Radiant, we offer both RFID and barcode asset tags, as well as comprehensive asset management software that makes it easy to track and manage your assets. Request your free demo below to see how our solutions can benefit your business.

Last Updated on September 15, 2022 by Radiant