Businesses have been struggling with the pallet shortage for a while now and unfortunately, it doesn’t look like things will be getting better anytime soon. So what can businesses do to overcome this challenge? One potential solution is pallet tracking.

What is Pallet Tracking?

Pallet tracking can help businesses keep track of their pallets and make sure they are being used efficiently. This can potentially help businesses reduce the number of pallets that are wasted each year.

Read on to learn more about how pallet tracking can help you overcome the challenges of the pallet shortage.

The Important Role of Pallets in a Supply Chain

In the supply chain, a pallet is an often overlooked but essential piece of equipment. They provide a stable, standardized platform for storing and transporting goods, as well as raw materials. This allows companies to efficiently move large quantities of products from one location to another.

Additionally, pallets help to protect products from damage during shipping and handling. They also make it easier to load and unload trucks, as well as to stack products on shelves.

As a result, pallets play a vital role in ensuring the smooth flow of goods throughout the supply chain. With their versatility and durability, wooden pallets are an essential tool for keeping the world economy moving.

How Misplaced Pallets are Contributing to the Pallet Shortage

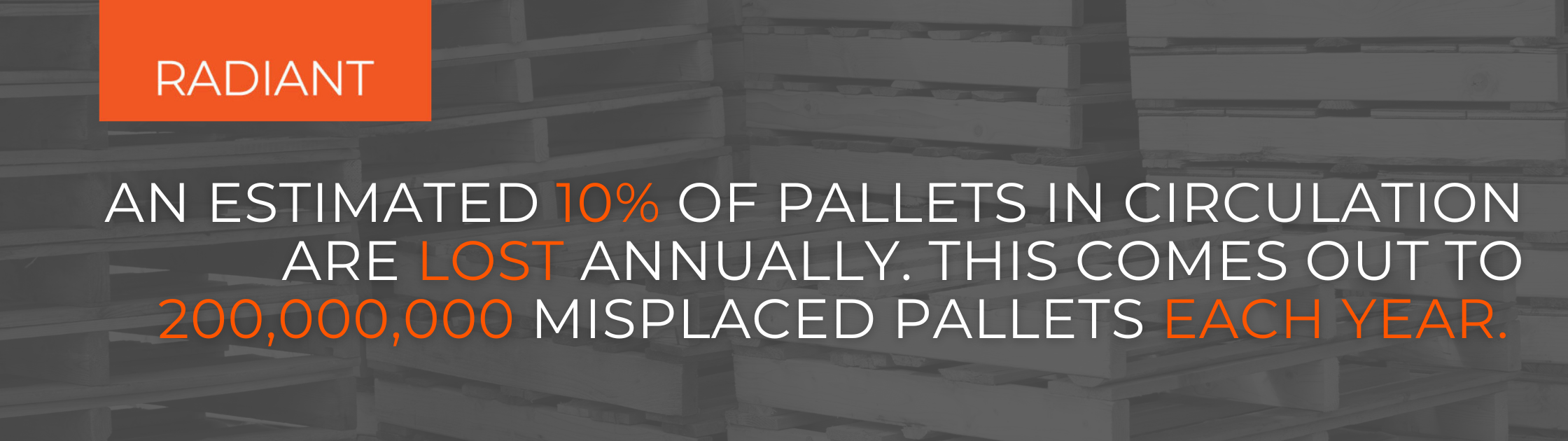

Recently, the United States has seen a nationwide shortage of pallets. While the reasons for this shortage are complex and varied, one contributing factor is the misplacement of pallets in the supply chain.

When pallets are not returned to their original owner after being used to transport goods, it creates an imbalance in the supply and demand of pallets. This shortfall must then be made up by purchasing new pallets or by renting them from pallet providers. The cost of new or rented pallets can be significant, and it ultimately gets passed on to consumers in the form of higher prices.

To help alleviate the pallet shortage, it is important to ensure that all pallets are returned to their rightful owner after use. By closing the loop in the supply chain, we can help keep costs down and ensure that there are enough pallets to meet demand.

How Pallet Tracking Can Help in Overcoming the Challenges of the Pallet Shortage

A pallet tracking system can help overcome this challenge by providing real-time visibility into the whereabouts of each pallet. This information can help businesses to recover lost or stolen pallets, which can otherwise be costly and time-consuming to replace.

In addition, a pallet tracking system can be used to optimize shipments, identify potential delays, and ensure that goods are delivered on time. By implementing a pallet tracking system, businesses can accurately track and manage pallets to overcome the challenges created by the national pallet shortage.

Not only will they be able to keep track of their own inventory, but they will also be able to make more informed decisions about where and how to ship their goods. As a result, businesses that implement an efficient tracking system will be better equipped to weather the current shortage and come out ahead of their competition.

What is a Pallet Tracking System and How Does it Work?

A pallet tracking system is a method of identifying and tracking pallets throughout the supply chain using IoT connectivity. Pallet tracking systems work by assigning each pallet a unique ID number. This ID number is then linked to a sensor tag that is affixed to the pallet. In the case of smart pallets, these tracking sensors are built-in as part of the manufacturing process.

As the pallet moves through the supply chain, its location is tracked by reading the sensor at each location. The data from these scans is then transmitted to a central database, where it can be accessed by shippers, receivers, and other members of the supply chain.

There are several common technologies used in pallet tracking systems: Barcodes, NFC, RFID, GPS and BLE:

![]()

- Barcodes are the most widely used pallet tracking technology, as they are cost-effective and easy to implement. However, barcodes can only be read from close range, making them less suitable for tracking pallets over long distances.

- NFC Pallet Tracking, or Near Field Communication tags can be read even when they are not within line of sight of the reader, but they require special NFC-enabled devices in order to be read.

- RFID Pallet Tracking, or radio frequency identification, uses RFID tags that emit radio waves to communicate with a reader. The reader then sends the information to a computer, which can track the location of the pallet.

- GPS Pallet Tracking, or global positioning system, uses satellite signals to track the location of a pallet.

- BLE, or Bluetooth Low Energy Pallet Tracking uses small devices called beacons that emit signals that can be detected by a smartphone or other device. The beacon then sends the information to a computer, which can track the location of the pallet.

All of these technologies have their advantages and disadvantages, but all can be used to track the real-time location of pallets as they move through the supply chain.

The Benefits of Implementing a Pallet Tracking Solution

Implementing a pallet tracking system has a number of benefits for businesses.

Perhaps most importantly, it can help to improve the efficiency of operations by providing enhanced visibility into the supply chain. By having a clear and up-to-date record of where each pallet is located, businesses can save time and money by avoiding the need to search for lost or misplaced pallets.

In addition, a pallet tracking system can help to improve safety by providing a record of which pallets have been damaged or are otherwise not safe to use. This information can be used to make sure that only quality pallets are used in the shipping process.

Finally, pallet level tracking can also help businesses to keep track of their inventory levels and better forecast future needs. By having accurate and up-to-date data on hand, businesses can avoid surprises and ensure that they always have the necessary supplies on hand.

Overall, implementing a pallet tracking system can provide a number of benefits for businesses of all sizes, while also helping to overcome the challenges created by the pallet shortage.

Are You Keeping Track of Your Pallets?

It’s clear that pallets play a critical role in the supply chain and without them, businesses would be unable to move their products. Unfortunately, misplaced pallets are contributing to the current pallet shortage. As the market for pallets tightens, it is more important than ever to have an effective pallet tracking solution in place.

At Radiant, we offer a comprehensive pallet tracking system that can help you optimize your supply chain and improve your bottom line. If you are interested in learning more about our asset tracking solution, please explore our website or request your demo below.

Last Updated on September 13, 2022 by Radiant