As a manufacturing business leader, you’re faced with a difficult challenge: how do you manage the labor shortage while also staying competitive in today’s market?

This can be an especially daunting task as demand continues to increase across industry sectors and global labor supply remains limited. You know your business needs to innovate or risk being left behind by your more agile competition.

Luckily, one solution may make all the difference – IoT technology. With its array of data-driven solutions, incorporating the Internet of Things (IoT) into operations could provide just what manufacturers need to strengthen their workforce and remain competitive in the face of increasing demands on production.

In this blog post, we’ll look at some practical ways businesses can start leveraging IoT solutions to help combat the current manufacturing labor shortage.

Why Is There A Manufacturing Labor Shortage?

It’s no secret that the American manufacturing industry has seen a significant labor shortage in recent years, and the reasons for this shortfall go beyond the pandemic’s effect, which has undoubtedly contributed to the problem significantly.

While there are multiple factors at play, one of the most prominent is an aging workforce. As baby boomers retire, their vacant positions are often harder to fill since younger workers frequently do not see manufacturing as a desirable career path.

Additionally, technological advancements have changed the nature of many manufacturing jobs, requiring more advanced skills and education from the labor force. As a result, traditional manufacturing employment options may no longer be attractive to many job seekers.

These shifts pose significant challenges for businesses that rely on a steady stream of skilled labor to keep their operations running smoothly. As we consider ways to address this mounting scarcity of manufacturing workers, it will be essential to prioritize innovative solutions that highlight the opportunities and potential for growth within the modern manufacturing sector.

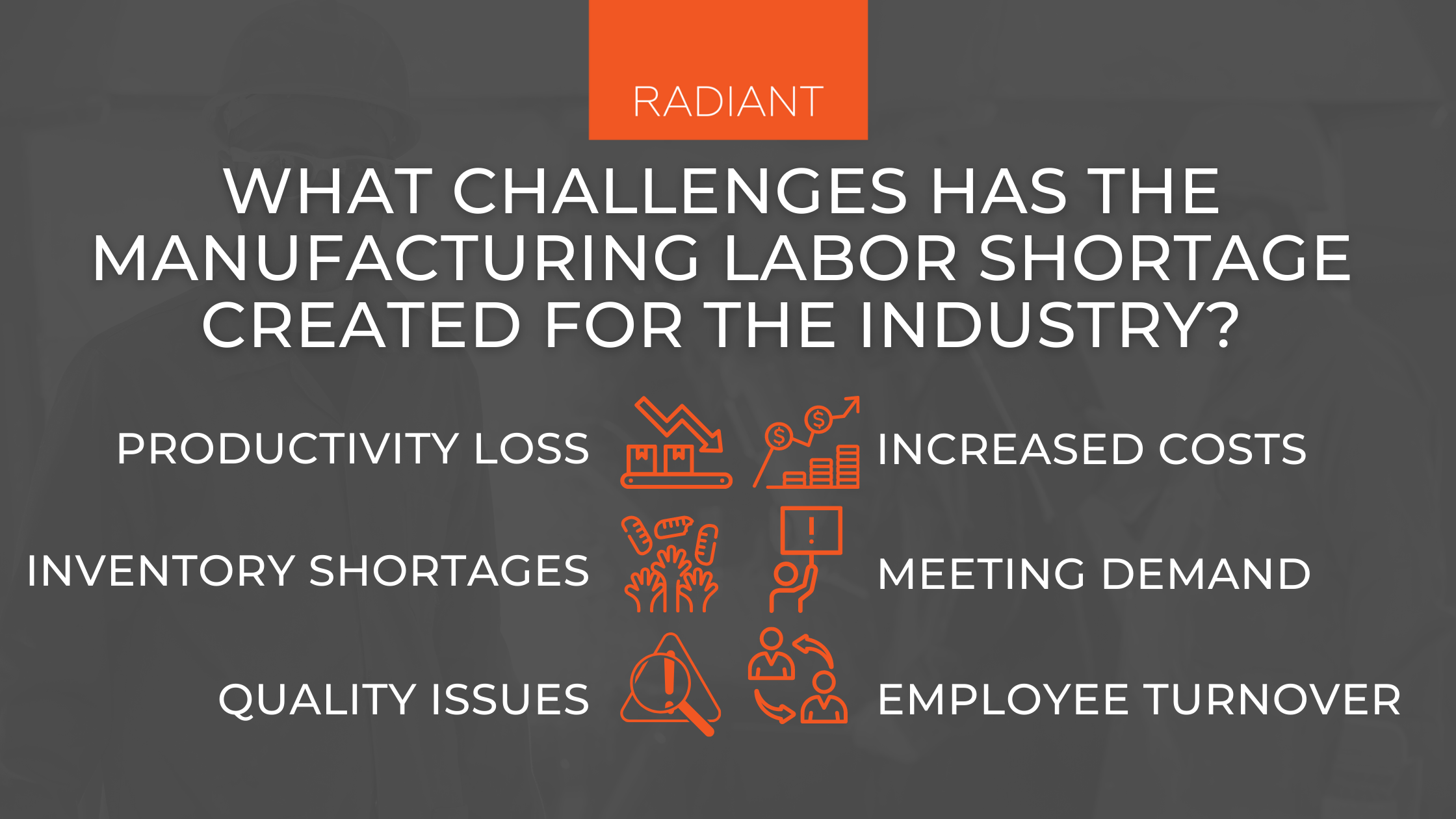

What Challenges Has The Manufacturing Labor Shortage Created For The Industry?

The manufacturing sector’s ongoing labor shortage is leaving businesses within the industry to face unprecedented challenges with a growing number of job openings, including:

Productivity Loss

The most direct consequence of the manufacturing labor shortage is a loss in productivity. With fewer skilled workers available to man the assembly line, businesses are forced to slow down production or even stop it altogether. This not only results in a loss of revenue but also puts a strain on the business’s supply chain as orders go unfulfilled.

Increased Costs

Another consequence of the manufacturing labor shortage is increased costs. Businesses are forced to pay higher wages in order to attract and retain workers. Additionally, they may also incur higher costs for training new employees and for overtime pay.

Difficulty Meeting Demand

The manufacturing labor shortage has also made it difficult for businesses to meet customer demand. With production slowed or halted due to a lack of workers, businesses are unable to keep up with customer demand, leading to lost sales and frustrated customers.

Inventory Shortages

The manufacturing labor shortage has also led to inventory shortages for businesses. With production slowed or stopped, businesses are unable to replenish their inventory, leading to out-of-stock items and lost sales.

Quality Issues

Another consequence of the manufacturing labor shortage is an increase in quality issues. With fewer workers available to man the assembly line, there is a greater chance for mistakes to be made, which can lead to defective products being shipped out to customers.

Employee Turnover

The manufacturing labor shortage has also resulted in increased employee turnover as workers leave for better-paying jobs elsewhere. This not only leads to higher training costs for businesses but also decreases morale and can lead to a decline in product quality.

While these challenges may seem daunting, to the industry that invented innovation, the manufacturing labor shortage can also present opportunities for growth and progress.

How Can IoT Solutions Help In Addressing The Manufacturing Labor Shortage?

Just as the causes of the manufacturing labor shortage are multifaceted, so too will be the resolution. However, these obstacles are leading more manufacturers to turn to technology, and for a good reason– IoT solutions can help manufacturing businesses overcome many of the challenges created by the labor shortage while also driving innovation and, ultimately, creating a better industry for workers to be a part of.

For example, by leveraging cloud computing, businesses can automate many of their time-consuming, manual processes and increase operational efficiency while reducing costs. This can enable them to keep production running and minimize downtime even with fewer workers on the assembly line.

IoT solutions also allow manufacturers to collect and analyze real-time data collected by IoT devices to identify trends and optimize operations. This can provide an informative insight into customer demand, allowing businesses to more accurately predict future needs and adjust their production accordingly.

Additionally, IoT solutions make it easier for businesses to track employee safety and asset performance in order to maintain quality standards without needing a large workforce. This can ensure that customers receive only the highest quality products and provide manufacturers with a competitive edge in the market.

Finally, by taking advantage of IoT solutions, manufacturers can not only combat the labor shortage but also create an innovative industry with better working conditions for its employees.

With innovation at the forefront and improved processes in place, businesses will be better equipped to manage customer demand now and into the future. Ultimately, this means a healthier bottom line for companies and a brighter future for manufacturing as a whole.

To receive a monthly newsletter highlighting our newest and most popular blogs, sign-up below.

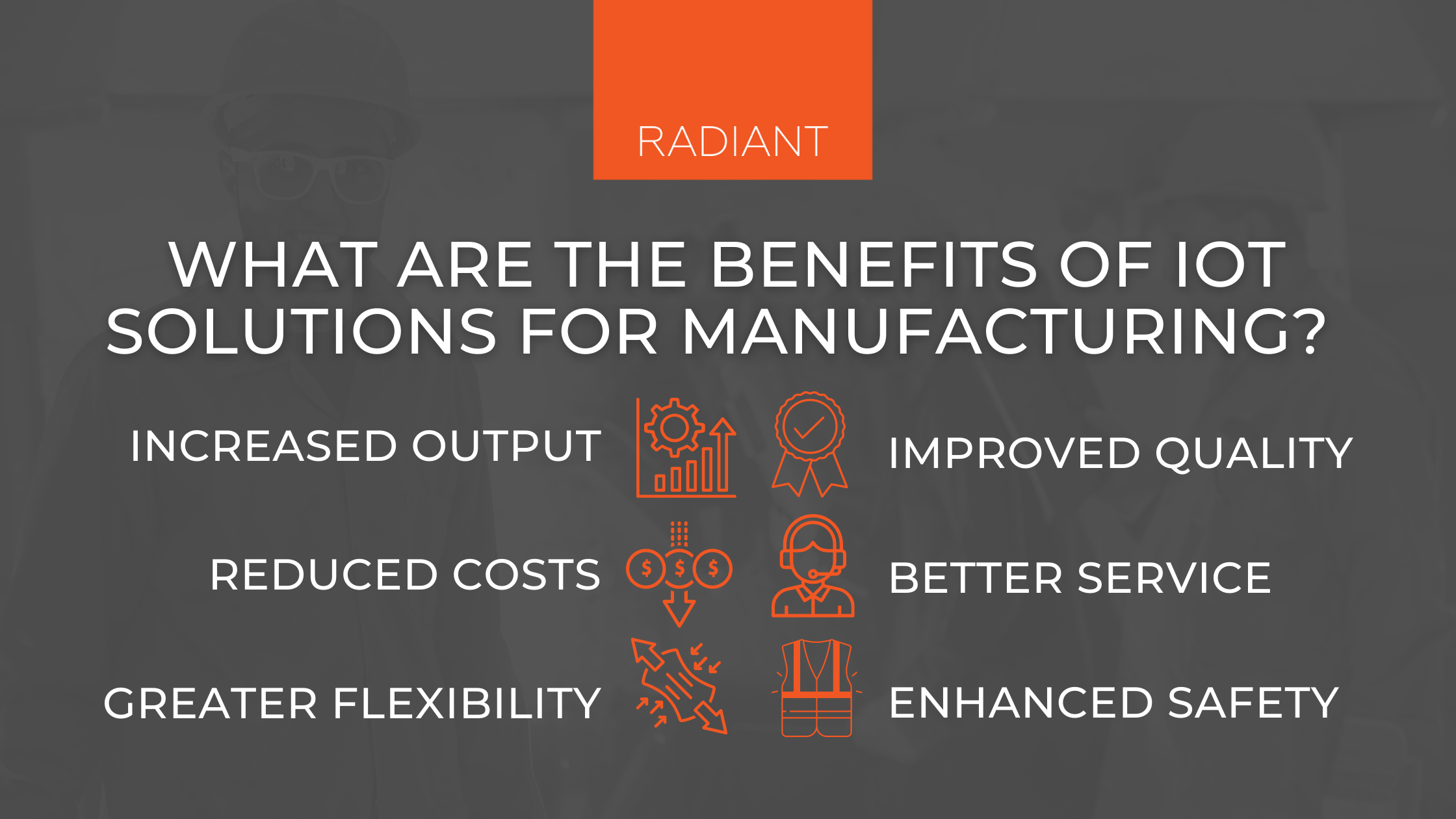

What Are The Benefits Of IoT Solutions For Manufacturing?

It’s easy to see that IoT solutions provide a powerful tool for overcoming the challenges created by the manufacturing labor shortage, but they can also provide businesses with a wide range of benefits, including:

Increased Productivity

One of the primary benefits of IoT solutions for manufacturing is increased productivity. By collecting data from various machines and processes, manufacturers can identify inefficiencies and bottlenecks. This data can then be used to make improvements that result in a more efficient production process.

Improved Quality Control

IoT solutions can also be used to improve quality control in manufacturing. By tracking data throughout the production process, manufacturers can identify when and where quality issues are occurring. This data can then be used to make changes that improve the quality of the final product.

Reduced Costs

Another benefit of IoT solutions for manufacturing is reduced costs. By improving productivity and quality control, manufacturers can reduce the amount of waste and rework that is required. Additionally, IoT solutions can help manufacturers to reduce energy consumption by monitoring and managing equipment usage.

Better Customer Service

Adopting IoT solutions for manufacturing can also enhance customer service. By tracking products throughout the supply chain, manufacturers can provide customers with real-time visibility into the status of their orders. Additionally, IoT solutions can be used to automatically notify customers of any delays or issues that may arise.

Greater Flexibility

IoT solutions also offer manufacturers greater flexibility in terms of production. By collecting data on how machines are being used, manufacturers can quickly adapt their production processes to changing demands without having to make major changes to their infrastructure. Additionally, IoT solutions make it possible for manufacturers to quickly scale up or down their production as needed.

Enhanced Safety

IoT solutions can also enhance safety in manufacturing environments. By tracking data throughout the production process, manufacturers can identify potential hazards and take steps to mitigate them. Additionally, IoT solutions can be used to monitor equipment usage and performance, which can help to prevent accidents and injuries.

Such benefits offer manufacturers a competitive edge in an increasingly crowded market; a smart and reliable manufacturing process that leverages IoT solutions is a crucial investment for any modern organization.

The Future Of The Manufacturing Industry & IoT Solutions

The manufacturing industry is at a pivotal point in its evolution, and IoT solutions are the key to that growth. Those companies that have the foresight to invest in innovative IoT solutions are sure to have an advantage over those that do not.

Imagine a factory where every machine is interconnected and data is collected in real-time, providing total asset visibility. This allows for increased efficiency, productivity, and flexibility.

Moreover, such companies will become more appealing to today’s workforce. With an industry experiencing a labor shortage, the time to modernize and offer the next generation opportunities to work with cutting-edge technology is now.

Embracing IoT solutions is the answer to this challenge. The future of manufacturing belongs to those who grasp this opportunity.

Ready To Innovate And Modernize Manufacturing With Radiant’s IoT Solutions?

In today’s world, the worker shortage in manufacturing has become an increasingly serious issue for many businesses. It is essential for businesses to create a plan of action that includes modernizing their processes with IoT solutions to prevent any further productivity losses or cost increases despite the growing number of unfilled jobs.

By utilizing solutions from Radiant, businesses can take advantage of all the benefits the IoT technology brings to the table, such as increased productivity, improved quality control, reduced costs, better customer service, and enhanced safety. With our help, you have the opportunity to revolutionize your business operations and make your manufacturing more efficient long term.

To start this journey towards success, explore our IoT solutions and request your demo below. Through innovation with Radiant’s cutting-edge technology, you can build a stronger future for yourself and your company. Don’t let the labor shortage stand in your way of progress – let us guide you in your endeavors to revolutionize manufacturing.

Are you ready to learn more? Request a demo.

Last Updated on May 1, 2023 by Radiant