Are you a business leader looking for information on Industrial IoT (IIoT)? If so, you’ve come to the right place.

In this blog post, we will cover everything there is to know about IIoT and its associated solutions. From providing detailed insights into what IIoT is to exploring how it can change your operations and give better visibility over assets across multiple locations – we have you covered. Get ready to discover all the potential of IIot-enabled asset management.

What Is Industrial IoT (IIoT)?

In today’s world, IoT technology and industry have become inseparable through the Industrial Internet of Things, or IIoT. This concept refers to the integration of IoT sensors, analytics, and software into industrial machines and processes, allowing for real-time data monitoring and analysis.

Essentially, IIoT focuses on connecting all aspects of an industrial operation and leveraging big data to improve efficiency, reduce downtime, and increase overall productivity.

As the demand for more intelligent manufacturing and production processes continues to grow, businesses are turning to IIoT devices to optimize their operations and stay ahead of the game.

It’s safe to say that the future of industrial operations lies in the power of IIoT.

How Does Industrial IoT (IIoT) Work?

Industrial IoT refers to a system of interconnected devices and sensors that collect and share data to make industrial processes more efficient and effective.

Essentially, it allows machines to communicate with each other and with humans in real time, providing insights and automating tasks that were once handled manually. The beauty of IIoT is that it provides unprecedented visibility into the production process, enabling manufacturers to be proactive and take corrective action before issues escalate.

This technology is revolutionizing industries such as manufacturing, automotive, oil and gas, and logistics by enabling predictive maintenance, optimizing supply chains, and improving overall product quality. Through the use of sensors and advanced analytics, Industrial IoT is able to provide key insights that can help organizations make better-informed decisions, reduce waste, and ultimately improve their bottom line.

In a nutshell, IIoT allows for smarter decision-making, greater efficiency, and streamlined operations.

What Are The Benefits Of Industrial IoT (IIoT) For Businesses?

The benefits of IIoT for businesses are many and varied.

Firstly, it allows for improved efficiency and productivity through the collection and analysis of vast amounts of industrial data. This provides businesses with valuable insights into their operations, enabling them to optimize processes, reduce costs and improve customer satisfaction.

Additionally, IIoT can enhance workplace safety by reducing human error and better monitoring equipment.

And finally, by enabling remote monitoring and control, IIoT enables businesses to operate on a global scale with greater ease and flexibility.

The benefits of IIoT are clear, making it an essential technology for businesses looking to improve their operational efficiency and stay competitive in today’s fast-paced digital landscape.

Use Cases For Industrial IoT (IIoT)

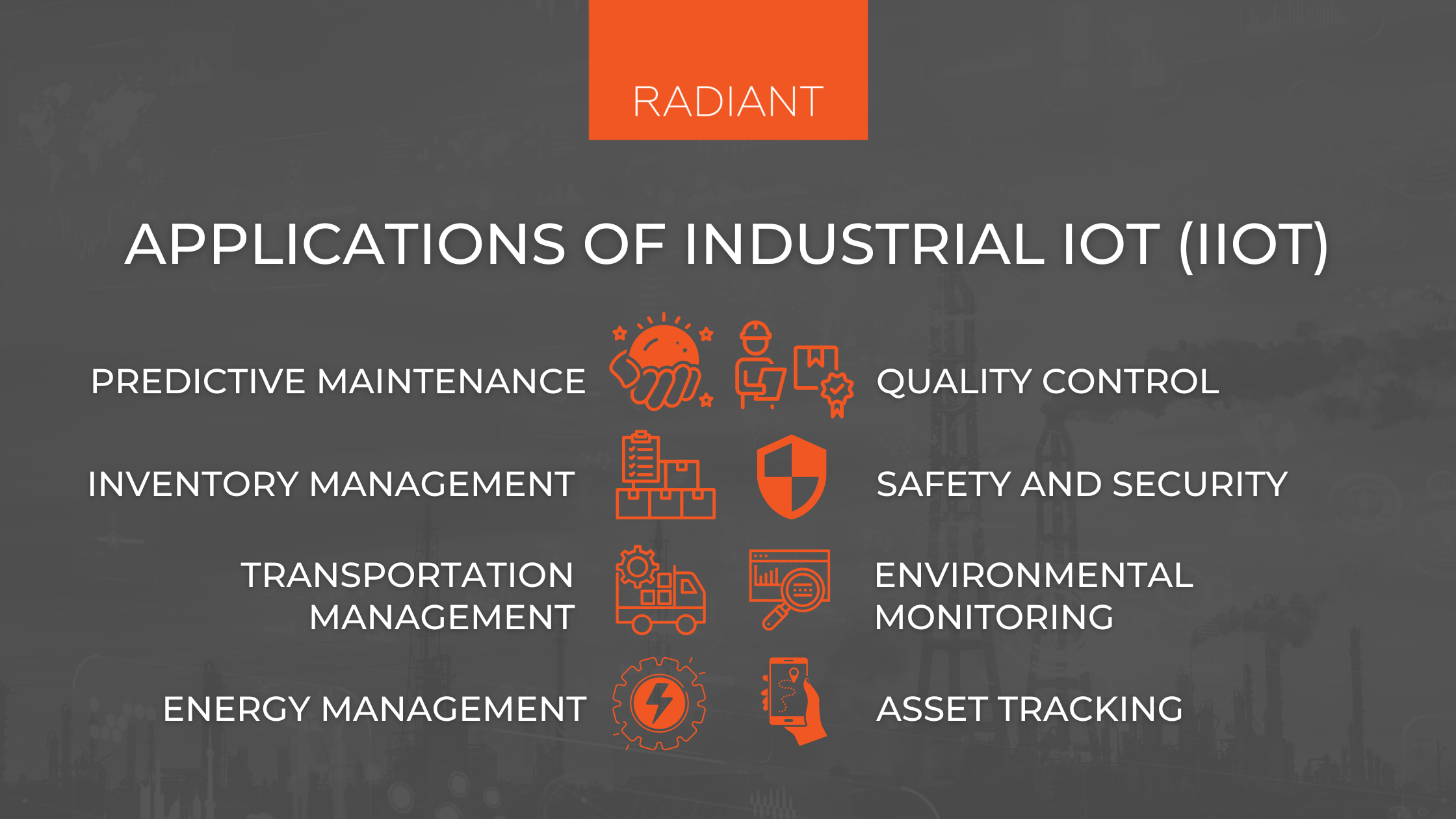

The possibilities of industrial Internet of Things (IoT) are endless, but some use case examples shine brighter than others:

– Predictive Maintenance: One of the most popular use cases for industrial IoT is predictive maintenance. By connecting sensors to machines, predictive maintenance systems can monitor the health of the machines in real time and predict when they are likely to experience a failure. This information can then be used to schedule maintenance before the machine breaks down, which can help to reduce downtime and improve productivity.

– Quality Control: Another common use case for industrial IoT is quality control. By connecting sensors to production lines, quality control systems can monitor the quality of products in real time and identify when there are issues. This information can then be used to make adjustments to the production process, which can improve the overall quality of the products.

– Inventory Management: Inventory management is a type of industrial IoT that can be used to improve the efficiency of supply chain operations. By collecting data from IoT sensors on inventory levels, inventory management can be used to optimize stock levels and minimize the need for manual inventory checks. This can help to reduce the cost of goods sold and improve customer satisfaction by ensuring that products are always available when needed.

– Safety and Security: Safety and security issues are another important use case for industrial IoT. By monitoring conditions in the workplace, it is possible to identify potential hazards and take steps to mitigate them. Additionally, industrial IoT can be used to monitor equipment for signs of tampering or theft.

– Transportation Management: Transportation management is another common use case for industrial IoT. By tracking the movement of goods throughout the supply chain, it is possible to optimize transportation routes and reduce costs. Additionally, this data can be used to monitor compliance with regulations such as hours of service rules.

– Environmental Monitoring: Environmental monitoring is another common use case for industrial IoT. By connecting sensors to environmental factors such as temperature, humidity, and air quality, industrial asset monitoring systems can track conditions in real time and identify when there are issues. This information can then be used to take action to improve conditions, which can help to protect people and equipment from damage.

– Energy Management: Energy management is a type of industrial IoT that can be used to improve the efficiency of energy use in manufacturing operations. By collecting data from sensors on energy consumption, energy management can be used to identify opportunities for energy savings. This can help manufacturers reduce their energy costs and their environmental impact.

– Asset Tracking: By leveraging sensors, networks, and data analytics, industrial IoT asset tracking allows businesses to monitor and manage their assets more effectively. This, in turn, leads to improved efficiency, reduced costs, and better decision-making. With industrial IoT, asset tracking is becoming a game-changer, providing businesses with the insights they need to optimize their operations and stay ahead of the competition.

Why Should You Consider Adopting Industrial IoT Solutions?

In this modern age, the rise of Industry 4.0 has revolutionized the manufacturing industry through the power of industrial IoT. With the Internet of Things holding a great deal of potential to streamline productivity, optimize resource allocation, and facilitate data-driven decision-making, organizations that adopt it today are the ones that stand to gain the most.

From real-time process monitoring to predictive maintenance and automated quality control, industrial IoT represents a significant shift from the traditional model of reactive maintenance to a far more proactive and preventative approach.

To stay competitive and maximize the full potential of IoT, businesses must be willing to adapt and embrace the new technological landscape swiftly.

At the end of the day, early adopters will undoubtedly reap the benefits of this exciting new era in IoT technology.

Get Started With Industrial IoT Today

In the end, industrial IoT holds impressive potential for businesses of all sizes, regardless of industry. By leveraging the power of connected devices and automated data capture technology, IIoT solutions can help businesses boost efficiency and productivity in ways previously unimaginable.

With use cases for virtually every industry ranging from Smart Manufacturing to Telemedicine, IIoT is here to stay – and it’s easy to get started with the right solution. Companies eager to break into the wonderful world of IIoT should explore their options carefully and determine which solution will best meet their needs.

To get started on your journey towards transforming your business operations with Industrial IoT solutions, take a minute to explore our IoT solutions for asset tracking and life safety, then request your demo below. We look forward to helping you embark on this exciting adventure.

Last Updated on May 18, 2023 by Radiant